Global Manufacturer of Cable Assemblies in Dallas, Texas USA

ISO 9001:2015

The quality of your product is the sum-total of your suppliers – choose wisely.

- Copper Assemblies

- Cabling Assemblies

- Wiring Harnesses

- Custom Molding

- Patch Cords

- WAN/LAN Assemblies

- Coaxial Assemblies

- SCSI Assemblies

- D-Sub Connectors

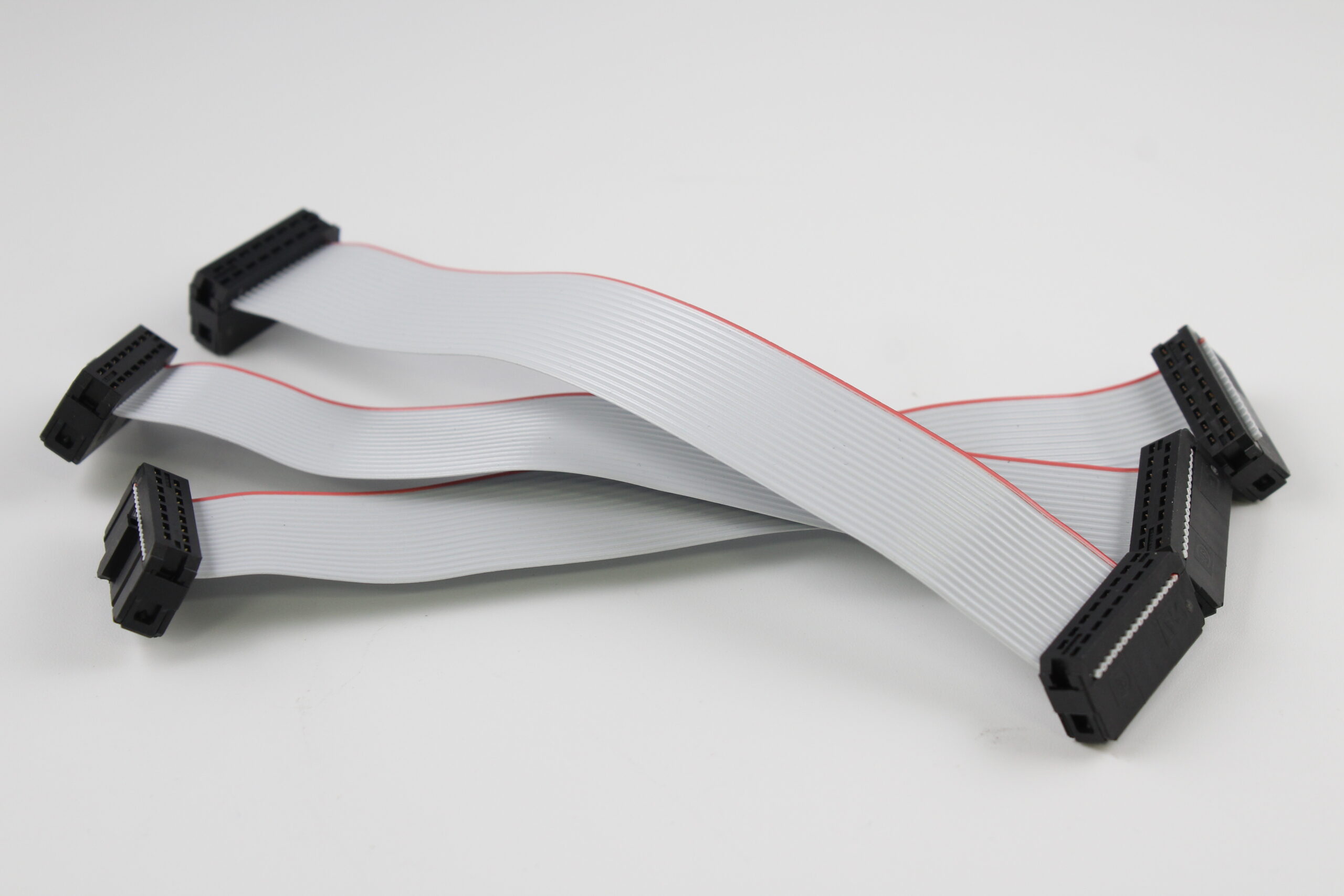

- Ribbon Assemblies

- Other Custom Cables

- Discrete Wire

- Grounding

- Power Cords

Over 40 Years of Expertise

Wallace Electronics is a Woman Owned Manufacturer of Custom Cable Assemblies and Electronic Enclosures. Located in Dallas, Texas, we have been providing our goods and services to the Electronics Industry since 1977.

At the core of everything are our People. We are committed to their Support and Development; they are committed to our Customers. Please take a moment to contact us and see why we have been in business for over 40 years.

Wallace Electronics

10551 Miller Rd, Suite 300/400 • Dallas, TX 75238 • 800-232-0404

Industries

- Industrial Automation

- Military

- Medical

- Automotive

- Lawn and Garden

- HVAC

- Lighting

- Telecom

- Gaming

- Security

- Solar

- Wind

- Sat Com

- Oil and Gas

- Food and Beverage

Why Wallace Electronics Is the Smart Choice for Custom Cable Assemblies

When your project depends on precision and reliability, the smallest connection can make the biggest difference. Whether you’re building medical devices, automation systems, aerospace hardware, transit equipment, or renewable energy solutions, your assemblies need to perform every time.

At Wallace Electronics, we do more than manufacture cables. We work alongside your team to make sure every build supports your design, your deadlines, and your standards.

Built Around Your Needs

Every project brings its own challenges. That’s why flexibility is central to how we work:

- Reverse-engineered assemblies built directly from your samples

- Connector-agnostic designs compatible with all major brands

- Custom shielding, pinouts, and overmolding for complex environments

- Engineering support that carries you from prototype through scaled production

Bring us in early for design input or hand us a finished spec, we’ll meet you where you are.

Quality You Can Rely On

Reliability is built into every stage of production.

- Continuity testing, pull tests, and electrical validation are standard

- Environmental testing available for vibration, temperature extremes, and outdoor use

- Full inspection reports and compliance documentation with every order

You get results you can verify with documentation and testing.

Industry Experience That Matters

Aerospace

Cables in aerospace applications face constant vibration, altitude shifts, and strict reliability demands. Our assemblies are engineered for resilience in high-stress conditions, using vibration-resistant construction and materials rated for extreme environments. When flight safety and mission success are on the line, our builds are designed to hold up.

Medical Devices

Medical equipment requires exacting standards, both in performance and compliance. We build clean-room compliant assemblies with options for overmolding, shielding, and low-voltage monitoring integration. Every order comes with full ISO and RoHS documentation, ensuring your devices meet regulatory approval without production delays.

Transportation: Bus & Rail

Transit systems put assemblies under constant vibration and exposure. We deliver armored, high-temperature, and corrosion-resistant cables that keep fleets running. Custom labeling and color coding make diagnostics faster, keeping downtime to a minimum, whether for retrofits or new installs.

Renewable Energy

Solar and energy storage projects require outdoor-ready designs that can handle UV, moisture, and high amperage. Our assemblies are voltage-rated, sealed against the elements, and available with flexible connector options for rooftop installs, microgrids, and large-scale storage systems. We also offer kitting and scaling support to keep deployment efficient.

Speed and Responsiveness

Prototypes often ship within 1-2 weeks. Lean manufacturing keeps costs under control while scaling smoothly into production. From fast quotes to clear communication, you’ll always know where things stand.

A Partner in the Process

We go beyond the build itself with support designed to simplify your operations:

- Design-for-Manufacturability consulting to reduce costs without sacrificing function

- Stocking programs and drop-shipping to fit your logistics

- Blanket orders and inventory planning for predictable supply

Our goal: take friction out of your supply chain so you can focus on growth.

Ready to Get Started?

At Wallace Electronics, you’ll find more than a vendor, you’ll find a partner who understands the technical, regulatory, and operational pressures of your industry.

Choose Wallace, and you get precision, reliability, and peace of mind, every time.

Frequently Asked Questions

About

What does Wallace Electronics specialize in?

We design and manufacture custom cable assemblies, wiring harnesses, and electronic enclosures for industrial, aerospace, medical, and military applications.

How long have you been manufacturing cable assemblies?

We’ve been serving OEMs and contract manufacturers since 1977, combining decades of experience with modern production methods.

Is your business woman‑owned?

Yes, Wallace Electronics is proudly woman‑owned, bringing diversity and leadership to the manufacturing sector.

What certifications back your quality?

Our facility is ISO 9001:2015 certified, UL‑approved for wiring harnesses, and IPC member‑audited to maintain consistent quality.

How do you handle regulatory compliance?

We meet UL material traceability, RoHS, REACH, and conflict minerals requirements, with documented processes and quarterly audits.

Product & Technical Capabilities

Do you make custom cable assemblies?

Yes, we manufacture custom cable assemblies in a wide range of configurations, from simple leads to complex multi‑conductor builds.

What wire gauges and materials can you work with?

We produce assemblies from 30 AWG to 2/0 using PVC, silicone, Teflon, and other industry‑approved materials.

Can you build wiring harnesses for specialized equipment?

Yes, we design and produce wiring harnesses for aerospace, medical, military, and industrial automation equipment.

Do you offer custom overmolding services?

Yes, we provide in‑house overmolding for custom connectors, ensuring durability and a professional finish.

Can you work with my preferred connector brand?

Yes, we work with every major connector manufacturer and have over 300 applicators in‑house for precision terminations.

What types of custom cable assemblies do you manufacture?

We design and manufacture a wide range of custom cable assemblies, including discrete wire harnesses, coaxial assemblies, multi-conductor cables, and ribbon cables. Every solution is engineered to meet your specifications.

Can you accommodate specific connector types and pinouts?

Absolutely. We work with virtually all major connector brands and configurations and can build to custom pinouts as needed—whether from drawings, samples, or your engineering specs.

Do you offer cable overmolding or shielding for EMI protection?

Yes, we provide overmolding options for durability and environmental sealing, as well as shielding techniques to mitigate electromagnetic interference (EMI).

What is your typical turnaround time for prototyping and production?

Prototypes can typically be produced within 1–2 weeks, and production lead times vary based on volume and complexity. We’ll provide accurate timelines during quoting.

Are your assemblies compliant with industry standards (e.g., UL, RoHS, ISO)?

Yes, we adhere to applicable UL, RoHS, and ISO guidelines and can provide documentation to meet your compliance requirements.

Manufacturing & Quality

What quality control processes are in place to ensure reliable performance?

We follow rigorous quality protocols, including visual inspections, pull tests, and continuity checks. Every cable is verified before shipment.

Do you conduct environmental or electrical testing on your cable assemblies?

Yes—our capabilities include resistance testing, dielectric strength checks, and specialized validation depending on your application’s needs.

Can you meet volume production requirements while maintaining precision?

Whether it’s a single unit or a large-scale rollout, we scale production without compromising quality thanks to our lean manufacturing approach and skilled technicians.

Do you provide documentation such as inspection reports or certificates of compliance?

We provide test reports, certificates of compliance, and first article inspection data upon request.

Design & Customization

Can you assist with cable design or engineering support?

Yes, our engineering team can help refine your design, suggest improvements for manufacturability, and ensure optimal functionality.

What file formats do you accept for schematics or drawings?

We accept most standard formats including PDF, DXF, DWG, and Excel-based BOMs. If you have legacy documentation, we’ll work with it too.

Do you offer strain relief or color-coded wiring options?

We offer various strain relief methods and color-coded wires for easy identification, safety, and assembly accuracy.

Can you replicate an existing cable assembly if we send a sample?

Yes, we can reverse-engineer assemblies from samples and suggest improvements to enhance performance or reduce cost.

Industries & Applications

What industries do you typically serve?

We support clients in industrial automation, medical devices, aerospace, automotive, and telecommunications—among others.

Can you manufacture for aerospace applications?

Yes, we produce aerospace‑grade wiring harnesses and assemblies that meet ISO 9001:2015 and UL standards for avionics and control systems.

Do you make cable assemblies for medical devices?

Yes, we manufacture medical‑grade cable assemblies designed for reliability, sterilization, and compliance with industry regulations.

Can you handle projects for the military?

Yes, we produce rugged, high‑performance wiring harnesses and cable assemblies built for demanding military environments.

Do you make harnesses for renewable energy systems?

Yes, we design and produce custom wiring solutions for solar, wind, and other renewable energy applications.

Have you produced assemblies for environments like aerospace, medical, or industrial automation?

Yes, we’ve delivered assemblies for harsh and specialized environments including high-vibration aerospace settings and clean-room medical applications.

Do you offer solutions for outdoor or rugged environments?

Our ruggedized cable options include overmolded, sealed, and armored assemblies suitable for outdoor and industrial environments.

Quality & Compliance

Are you ISO certified?

Yes, Wallace Electronics is ISO 9001:2015 certified, ensuring consistent quality in every build.

Do your wiring harnesses have UL approval?

Yes, our wiring harnesses are UL‑approved and meet UL material traceability requirements in the U.S. and Canada.

How do you ensure product quality?

We follow documented quality control processes, IPC standards, and regular audits to maintain precision and reliability.

Do you comply with RoHS and REACH regulations?

Yes, we meet RoHS and REACH requirements and provide documentation upon request.

Do you source conflict‑free materials?

Yes, we comply with conflict minerals regulations under Dodd‑Frank Section 1502 and require supplier declarations.

Logistics & Ordering & Process

What's the minimum order quantity?

We’re flexible—whether you need a single prototype or a large batch, we tailor production to suit your needs.

Do you offer expedited production or delivery services?

Yes, we offer rush service options and expedited shipping when project timelines demand it.

How do I request a quote?

You can request a quote by sending your drawings, specifications, or sample to our sales team through our website or email.

Can you help with design support?

Yes, our engineering team can assist with design and material selection to ensure optimal performance and manufacturability.

Do you offer prototyping services?

Yes, we provide prototyping to validate designs before moving into full production.

What are your lead times for custom orders?

Lead times depend on design complexity and material availability, but typical orders ship within 2–4 weeks.

Can you drop-ship to our customers or distribution centers?

We do offer drop-shipping and blind shipments upon request for convenient fulfillment.

Partnership & Support

Do you offer long-term supply agreements or stocking programs?

Yes—we partner with clients on JIT delivery, blanket orders, and inventory programs to support continuous production.

Can we collaborate on DFM (Design for Manufacturability) to optimize costs?

Absolutely. We’re proactive in helping clients reduce cost without compromising performance.

Who do we contact for engineering support or technical questions?

Our dedicated support team includes engineers and account managers available to guide you from quote to delivery.

What is your return or warranty policy?

We stand behind our work with a satisfaction guarantee. If an assembly doesn’t meet your specs, we’ll make it right.

© 2022 Wallace Electronics, Inc. | Site: D2P Web Design

Wallace Electronics, Inc. | 10551 Miller Rd, Suite 300/400 | Dallas, TX 75238 | 800-232-0404